Shanghai as broadly purification equipment Co., LTD. In the original equipment foundation, and add a series of new advanced equipment, production process further improvement, the product quality and production efficiency and up a big steps, machine items as follows:

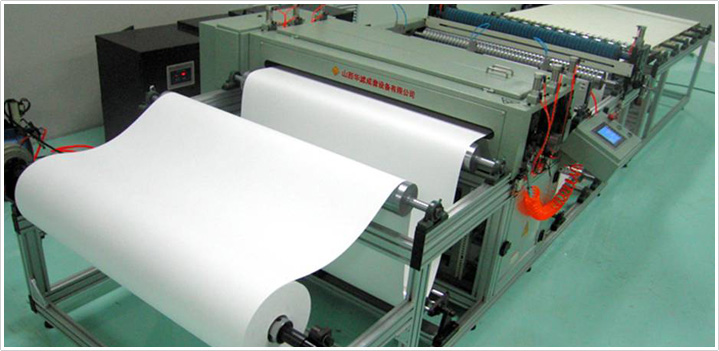

The most advanced automatic no hepa production line

Automatic production line adopts tinder barrier-free air filter machine, electricity, gas total control and high production efficiency. Simple operation, stable and reliable, and used in the production of glass fiber no clapboard air filter core; Can production must be within the scope of the high altitude without any products roll change machinery adjustment, as long as through the work station the height of the input for, can produce to meet the requirements of products; Along with the international advanced intermittent glue and counting broken glue function, which has greatly enhanced the equipment the practicability and stability of the product quality.

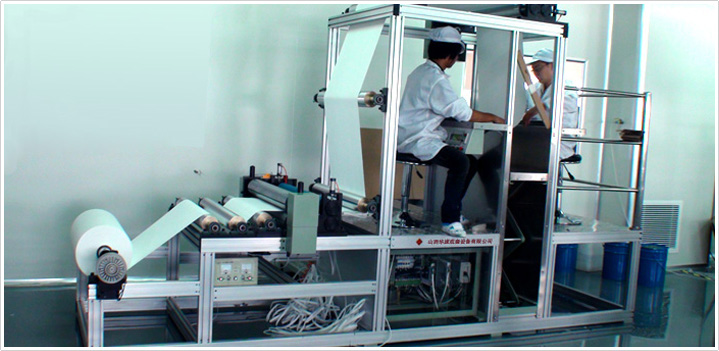

Have clapboard air filter production line

The equipment adopts machine, electricity, gas total control, used for superfine glass fiber filter nonwovens and corrugated shape clapboard as raw materials manufacturing have clapboard air filtration. Creasing and assembly forming complete integration, not only make product appearance are improved greatly, and greatly reduce the production process caused by human factors and cause of the damage of filtration material。

Have clapboard aluminum foil corrugated molding machine

采用PLCControl to achieve production automation; Can choose paper corrugated roller module in the machine in aluminum production and paper two material of corrugated boards; Can adjust the operating speed at any time; Scale adjustment by special institutions, simple operation, also can adjust online。

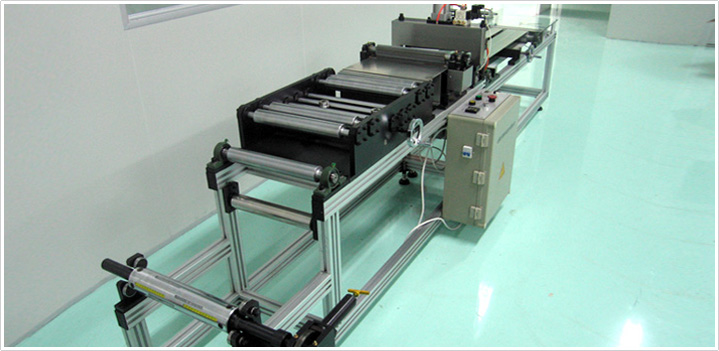

Folding filter production line

Reasonable discount knife trajectory, guarantee discount on sale process and sword will not touch each other; Avoid to cause the filtration material mechanical damage. Perfect control design realized the machine automatically run without human intervention.

Hydraulic sheet metal bending machine

USES the steel plate welding structure, and has good strength and stiffness, stable, safe and reliable, easy to operate, the upper die equipped with compensation institution, can ensure that you get higher bending work precision. Only equipped with various different mould, he can be sheet metal folding late or all kinds of different shapes of workpiece, also can undertake cutting, cut and process.

Hydraulic tilting plate shears

Used for shear thickness of0.5-4MM, width2500-4000MMof steel. The machine USES the steel plate welding structure, hydraulic rotation, nitrogen return cylinder return, work was stable and reliable, and the machine small volume, light weight, good rigidity. Adjust the blade gap rapid convenient, the machine before and after a block material, the mechanical rotation after block material, turn to count display numerical value and can be manual tuning, convenient adjustment and reliable, block the yardstick for before the count, block piece of positioning.

Aluminum cutting machine

Lu: xingcai cutting machine, also called profiles cutting machine, Angle and size scientific and accurate.

Believe that as broadly purification in equipment unceasing renewal, technical staff of technology of innovative and increasing based on, the subsequent will be presented to you in more high quality more satisfied with the filtering products, thank you for your support and we have to focus on!